Green materials boost processing

Researchers in Finland say eco-friendly chemicals can actually improve mineral processing.

Researchers in Finland say eco-friendly chemicals can actually improve mineral processing.

Experts at Aalto University have developed a new cellulose-based compound that is renewable, biodegradable and non-toxic.

Their research shows that it is also more effective in separating metals than the oil-based commercial frothers currently used.

The chemical technology used in froth flotation - the process through which metals are separated from ores - has remained relatively unchanged for decades.

“We wanted to find more sustainable alternatives to these chemicals, so we started carefully exploring cellulose derivatives with properties considered suitable for frothers,” says Dr Rodrigo Serna, a professor at Aalto University who came up with the idea.

“It was quite surprising when, already in the first laboratory experiments, the new compound started to produce more minerals than traditional methods.”

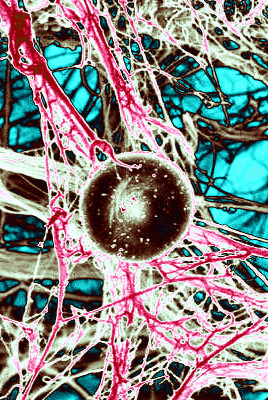

In the flotation process, air bubbles are created in a mixture of crushed ores, water and various chemicals.

The metal-bearing minerals selectively attach to the bubbles, forming a froth on the surface from which they are collected. Frothers are required to control the formation and stability of air bubbles.

Researchers found that the cellulose-based compound has several advantages over the state-of-the-art frothers now in use.

It increases the amount of minerals recovered, while accelerating the flotation process, and also works efficiently in a wider range of pH conditions, making it less sensitive to the changes in process conditions.

In some cases, like for zinc materials, the compound also helps reduce the need for chemicals in other aspects of processing as well.

The new materials have already been tested on tailings and waste slag from metal refineries. Researchers are currently experimenting the technology with minerals containing gold.

The team has applied for a patent for the technology under the name of CellFroth, and is moving to investigate commercialisation possibilities.

“The mining industry is under great pressure to develop more environmentally friendly practices,” Dr Serna says.

“At the same time, they need to improve their productivity as the need for raw materials increases and the mineral reserves become depleted. These don’t have to conflict with each other.”

Print

Print